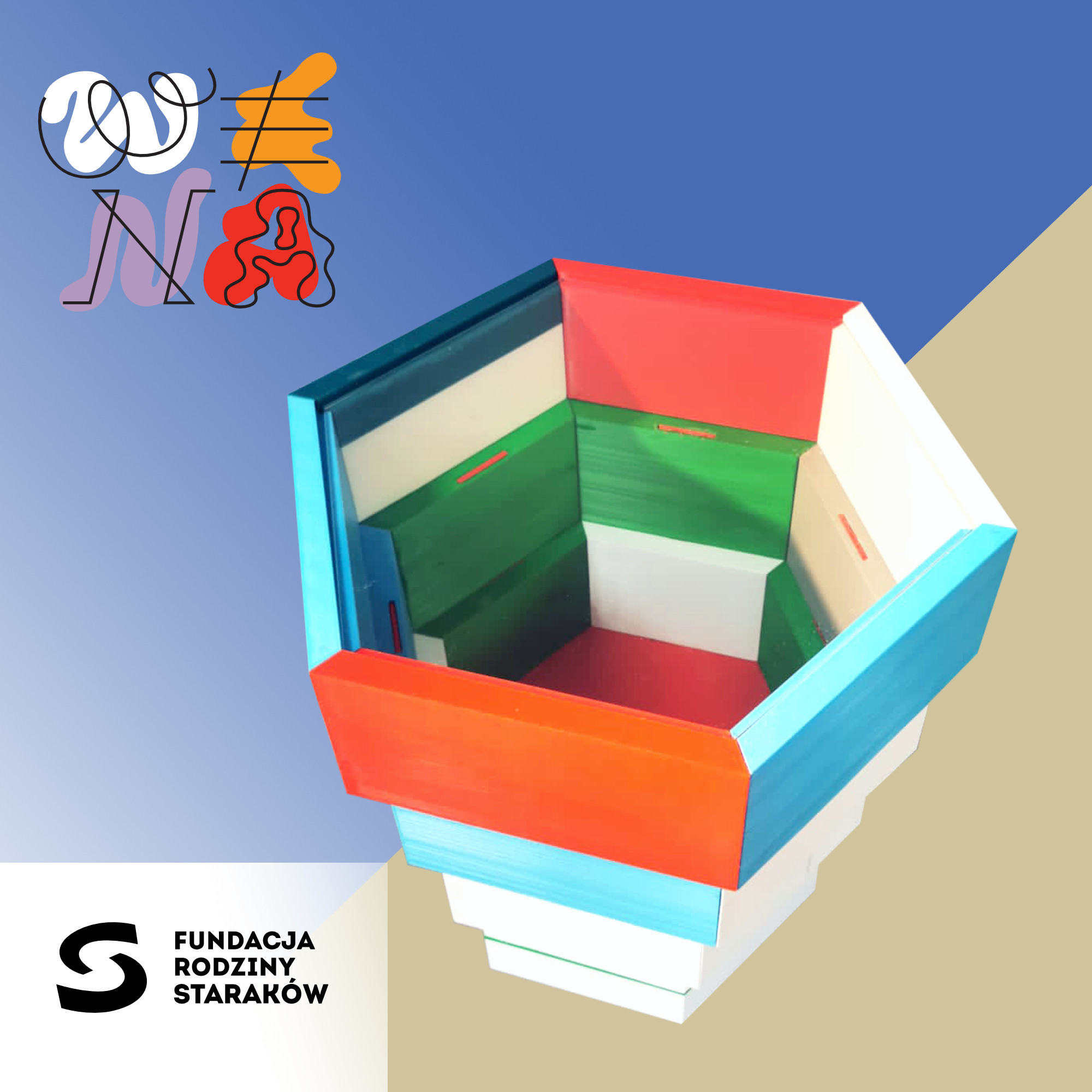

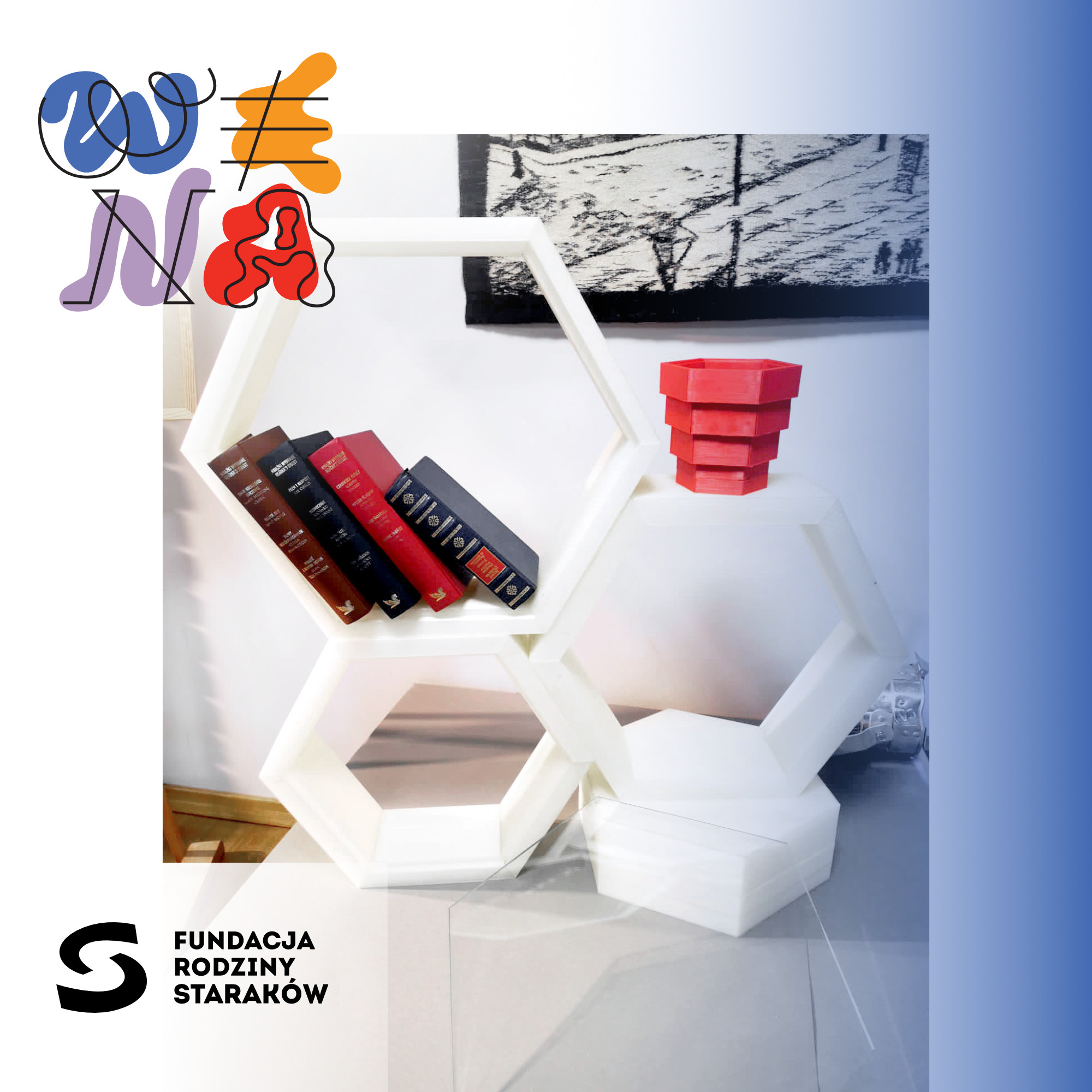

By taking part in the project, the students learnt the full spectrum of cutting-edge digital 3D printing techniques, as they created and designed furniture that was eco-friendly and promoted integration. The activities undertaken in the project, which went beyond the school core curriculum, had not only guided the students through all of the project activities, but also broadened the young artists’ horizons regarding recycling, design and arrangement of the school space. In this way, applied arts have contributed to the integration and increased comfort of the residents of the school’s boarding house.

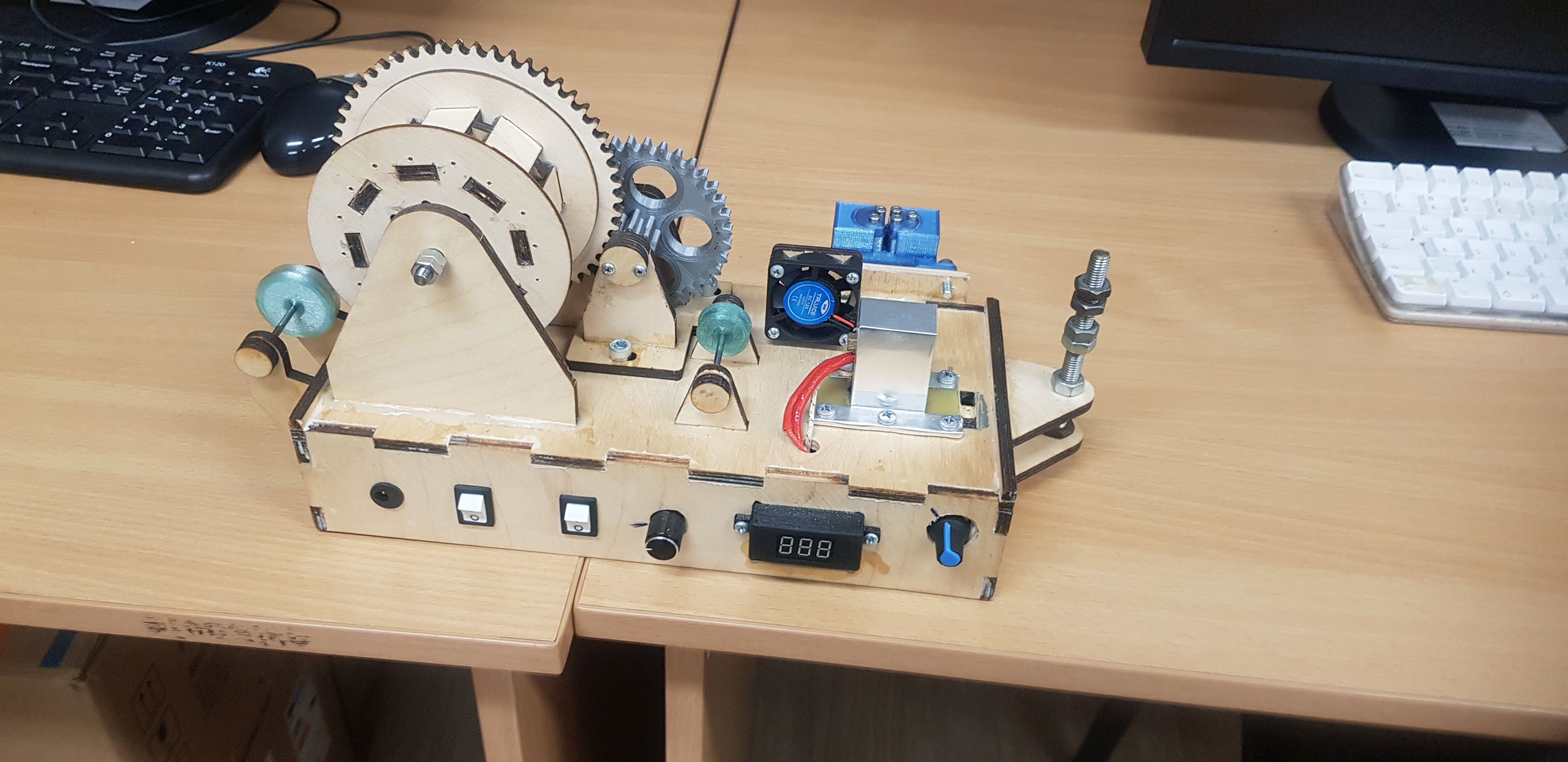

The project team made a device for recycling PET bottles and produced printing filament. The next step was the printing of a set of furniture to serve the students. The project was intended to transmute the ordinary and artificial material that is plastic into an attractive art form and, through the process, provoke a reflection of care for the environment. The project also had a social aspect, as it attempted to instigate change through a pro-environmental attitude and the integration of students. A set of furniture was designed, components were bought for a machine processing used PET bottles, and a prototype was constructed.

There was a change in the project during implementation. As the purchase of a large-scale 3D printer turned out to be impossible due to financial constraints, the teacher leading the project suggested buying cheaper components and assembling a 3D printer independently. The project leader has extensive experience in this type of construction work.

The project team consisted of six people: five 4th-graders and one 2nd-grader. Two 4th-graders and the 2nd-grader were given the design tasks, but they also participated in the construction and programming work. The remaining students assisted the project leader with the construction, testing and programming work. All the project participants were kept informed of the project progress. The teacher leading the project created a group on a social networking platform for ad hoc contacts between participants.

As a part of the project, the school has established cooperation with the Kielce University of Technology, Faculty of Mechatronics and Mechanical Engineering. The project is expected to deliver a set of furniture created from renewable materials. An exhibition of the deliverables has been planned. The target place to display the set is the garden at the school’s boarding house, where it will form a natural, permanent composition with its surroundings.

Schedule

- 3D printer assembly and testing - 01.2023

- Collection of bottles required for furniture printing - 01.02.2023-16.06.2023

- Production of filament from the bottles - 01.02.2023-16.06.2023

- 3D printing and construction of furniture according to design - 01.02.2023-16.06.2023

- Study visit to the Kielce University of Technology, to learn about modern 3D printing techniques - 07.06.2023

- Media campaign - 01.09.2022-09.10.2023

- Project conclusion - 09.10.2023

Results

Furniture created as part of the project is now used in the IT room. Six students gained skills in designing machines to create filament. Six students learnt to assemble and operate 3D printers, 1 person built a machine to produce filament from PET bottles. 1 person built a large-scale 3D printer to produce recycled furniture. The participants’ teamwork skills and self-confidence have improved significantly. The project team 3D-printed a set of furniture using renewable materials and built a prototype table from wood waste. The team is planning to continue the project by improving vers. 1.0 of the machine for converting PET bottle plastic into filament. The team is planning to make an attachment for automatic hot-gluing of individual pieces of the filament thus created. Vers. 2.0 of the machine converting plastic into filament is being developed; this one will be able to process any type of plastic.

Michał Łatasiewicz – project scheduler, multimedia and computer science teacher, manages a fleet of new technologies: 3D printers, a Gaia clay printer and a CNC machine tool.